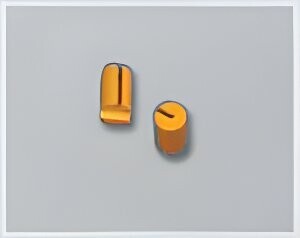

A connector manufacturer required insulators for military GPS applications. The part required machining Torlon because of the material’s heat resistance up to 500 degrees, as well as strong resistance to wear and chemicals.

We’ve been machining Torlon for decades, and our team brings their expertise to every project. This component required three primary operations: turning diameters, drilling holes, and milling grooves. Next, Severna Operations utilized a secondary operation, milling the slits thru. Then, we applied cryogenic and hand deburring to ensure the piece meets exact specifications.

As a full-service machine shop, Severna Operations designed and manufactured a custom tooling for this specific project: a unique saw tool to perform the slitting function while machining Torlon.

We have stringent quality standards, so we performed a 100%-dimensional inspection to ensure we met that standard.

These Torlon® components are used within a GPS application.

Strohms Swiss Automatic

Automatic Dividing Machine

Diameter: Ø.075″

Length: .120″

Slit Width: .010″

±.0005″

Torlon®

Natural

100% Dimensional Inspection

Connector

Military

United States

Customer supplied print, 2D CAD Drawing

Techtron PPS Insulator