What is Ultem® Plastic? It is a reliable and high-strength plastic designed to withstand extreme temperatures and powerful chemicals with a wide range of uses. This makes it an ideal choice for many industries.

With its superior strength and ability to resist harsh conditions, Ultem® Plastics has become the material of choice in many industries such as aerospace.

The aerospace industry has used Ultem® (PEI) Plastic for operation in extreme environments. What exactly is Ultem® plastic? Read on to discover everything you need to know about this versatile and high-strength plastic.

Ultem® plastic, also known as polyetherimide or PEI, is a type of high-performance thermoplastic used in a wide range of industries. It’s a semi-transparent, high-strength thermoplastic material that can operate in extreme temperatures.

It is highly resistant to hot water and steam and can withstand multiple cycles of sterilization in a steam autoclave with no risk of degradation.

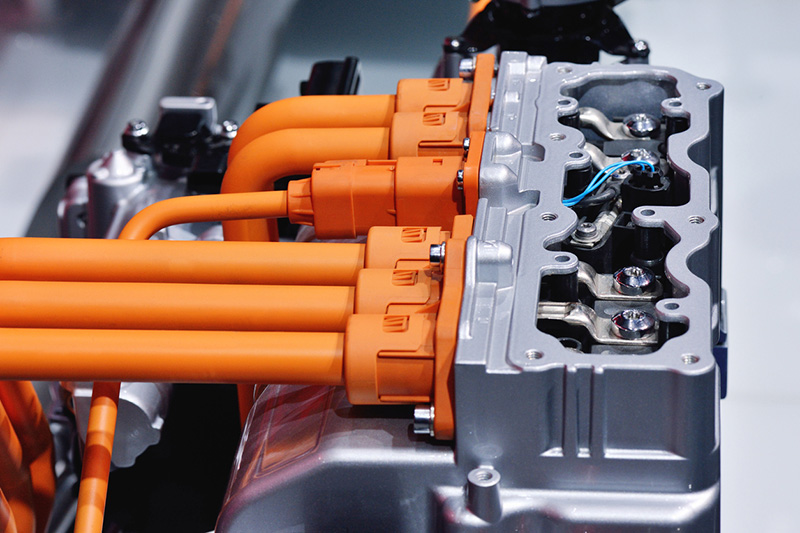

Additionally, Ultem® plastic has outstanding electrical properties including one of the highest dielectric strengths among all thermoplastics. FDA-approved grades are also available for use in food and medical applications.

You’ll find various industries utilizing the properties of Ultem® including medical, dental, aviation, outdoors, and electrical. Here are some typical uses for Ultem®:

It is a durable and strong material known for its excellent electrical, thermal, and chemical resistance. Additionally, Ultem® plastic has low flammability and smoke toxicity levels, making it an ideal choice for many applications.

The plastic was developed by General Electric Plastics Division (now known as SABIC) in the early 1980s, as a high-performance thermoplastic to be used mainly in the aviation industry.

It’s since been a popular choice for over 35 years, proving to be a reliable and durable material for a multitude of sectors.

Ultem® has long been a top choice for aerospace applications. It has been approved by the Federal Aviation Administration (FAA) and can meet the stringent mechanical standards and quality requirements needed for commercial aircraft parts.

When compared to other kinds of thermoplastics, Ultem® stands out in its resistance to creep, which is the tendency of materials to degrade and change form when exposed to prolonged stress.

This plastic is also resistant to many fuels, coolants, and lubricants, as well as flame-resistant per FAA regulations 25.853. Usage examples include fire blockers and airplane seat covers.

Ultem® plastic has a wide range of uses thanks to its performance characteristics.

Despite being extremely strong, it’s also easy to machine and fabricate without fear of it cracking and warping. Other desirable properties include its resistance to hydrolysis and chemicals.

Ultem® is a plastic material with many desirable properties. Here are some useful technical details about it.

Ultem® is just one brand name. Two other common brands of this material are:

Utem® 1000 is an unfilled, unreinforced thermoplastic that stands out for its special combination of mechanical, thermal, and electrical properties. It is translucent amber in color.

Glass-Filled Utem® 2300 is a glass fiber-reinforced plastic from the 2000 series that offers enhanced tensile strength, stiffness, and dimensional stability compared to its unfilled counterpart.

Ultem® is often chosen over polysulfone when additional strength, stiffness, or temperature resistance is needed.

Ultem® can be molded by thermoforming and created through a process known as Fused Deposition Modeling (FDM). In FDM, a heated nozzle follows a predetermined path and releases one layer of Ultem® at once until the desired product is fully formed.

Another cost- and time-effective way to create Ultem® products is Injection Molding. In the process, small pellets of thermoplastic are melted by a screw and injected into a mold where they cool and harden.

The finished part can then be removed with an ejector pin. This method of production is especially advantageous for creating repeatable parts in large quantities, such as burn-in sockets.

We hope this article has answered your questions about Ultem® plastic. It’s the perfect choice for any manufacturer looking for a material that is strong, stable, lightweight, and flame and chemical-resistant at the same time. It has the perfect combination of properties to make a wide range of products.

If you’re ready to take your plastic fabrication to the next level, speak to the team at Severna. We offer top-notch quality and service, unparalleled commitment to continual improvement, and cutting-edge machines and processes. Contact us today to get started.