If you’re interested in running your business more effectively, it’s important that you understand your trade and how manufacturing is done. Today, plastic prototype manufacturing is one of the most critical parts of the process that you can learn about.

The global plastic market is worth $609 billion today. There are several manufacturing companies available that can assist you at every stage.

This article will teach you all about plastic prototype manufacturing, how it is done, the benefits, and what you need to do to take advantage of it.

Companies often turn to prototyping before they send products to market. Today, this work is incredibly sophisticated and can help you in several ways.

What are some of the benefits that your company will appreciate?

Perhaps the first major benefit of plastic prototype manufacturing is that it is a technologically savvy project. You can’t half-step when it comes to your manufacturing, and this form of prototyping gives you efficiency and precision.

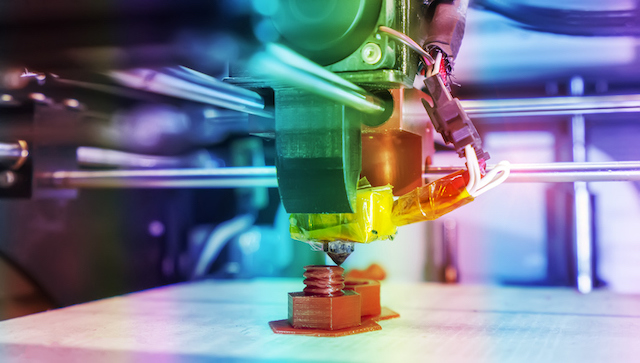

Companies today are manufacturing plastic prototypes in new and unique ways. Many pros are using 3D printing to turn around some high-quality plastic prototypes.

Manufacturers can fulfill large-scale orders without an issue, and you’ll appreciate that you get plenty of helpful information at a low financial risk.

If you hire the help of a company that provides plastic prototyping, you can include every detail possible. Custom manufacturing means that you get to work with your plastic material to create the precise shape, dimensions, and function that you’re looking for.

You’ll make fewer mistakes in the process and have a much lower concept risk since plastic is a less expensive material.

The major benefit of the plastic prototype process is that you won’t have to worry about as many mistakes in the long run. You’ll have a clear idea of your final product, what you can expect, and can troubleshoot for your consumers.

This makes the entire process less expensive and you’ll be able to hit the ground running.

Plastic prototyping is also helpful because it’s versatile. These services help companies in so many different industries.

A few examples of industries that make use of plastic prototyping include:

This versatility shows just how valuable this technology is and how you can get the most from it in your particular field.

Since the benefits are clear, you need to make sure that you follow the right steps to getting this work done. Knowing about the process and the different types of plastic machining available will help you make the right decisions.

Some of the main types of plastic prototype manufacturing that companies opt for include:

When you partner with a company that offers these services, you’ll be able to understand the pros and cons and can decide which type will work best for your needs. The company will be able to explain the process to you and make sure that you’re getting your intended results.

Before deciding on a company to do business with, make certain that you also come prepared with as many questions as possible. This will help you get the most from your prototype and you can plan the product in detail from start to finish.

For example, ask them about the parts diameter that they can accommodate you for. Companies might have a variety of parts diameters that they work with, ranging from .008 inches to 1.25 inches. Discuss your engineering requirements and ask about the inspection process to make sure that everything is aligned with your needs before moving forward.

Always make the company aware of your deadlines so that they can fulfill it in a turnaround time that works for your company. Learn how the prototypes are sourced and how they can help you with the design process. In most cases, the prototyping company will offer in-house CAM design services, but make sure of this before moving forward.

You should also find out exactly what types of materials they work with to see if this fits your needs. Companies that offer these services work with materials such as:

The more you know about the company’s process, the easier it’ll be for you to get a prototype that you find useful. You also owe it to yourself to get some price quotes that are detailed so that you can begin budgeting for the project.

Make sure to compare quotes with a few different companies before moving forward with any prototyping project.

The tips in this piece will teach you all about plastic prototype manufacturing. This is the type of work that you will get a lot from as long as you handle the project correctly. It all starts with understanding the process, and next, you can find a company that can carry it out for you.

Severna has spent several years mastering these processes. We can help you when you’re interested in getting the most from your plastics manufacturing. To request a quote, fill out our form or call us at 973-503-1600 today.