Plastic parts are affordable but effective components in various industries, including aerospace and automotive. With the ability to create any shape from a wide range of materials, plastics are flexible and versatile. As a result, they serve well for the prototyping process in determining exact tolerances and design considerations.

How to get plastic parts made? Let’s find out.

When commissioning plastic parts from a manufacturer, they must meet specific requirements. For one, they should understand the nature of your production and produce parts that don’t fail in the end-use of your project. Depending on your product size, you may also need them to offer fast turnarounds and work with flexible quantities.

Once you have found a credible manufacturer like Severna, what does the process for having plastic parts made look like? Below we explain the step-by-step process:

The first step to getting plastic parts made is to create a functional design. This is more than just a sketch. Your part design should include:

Now, it’s time to choose your materials.

Before getting your plastic parts made, you should determine the best material for your project. Several factors are worth considering, including cost, durability, surface finish, strength, and flexibility. The choice will depend mainly on how your plastic parts will be used. We work with a broad and flexible range of plastics for CNC machining and even 3D printing as a plastic manufacturer.

These include:

ABS provides the most flexibility for better processing and increased toughness. In addition, it has high tensile strength and is resistant to physical impacts and chemical corrosion.

Price is a significant consideration when having parts made for your project. If you are in the process of researching multiple vendors, it’s vital to get a fast and accurate turnaround on quotes so you can make the right choice. When you request a quote, include all necessary information from the start.

The key elements included in your quote request are:

If you’re working on a tight time constraint, this information will ensure you can get the production process started sooner. Be prepared to answer quickly and provide additional information and specifications.

As you research vendors to produce your machined plastic parts, you should also know which production method is most applicable. There are several ways to manufacture a plastic part.

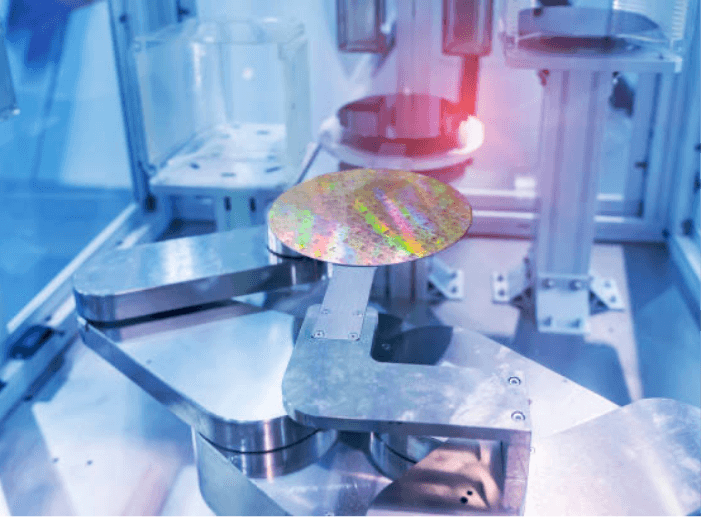

CNC machining services can create custom-machined parts that meet exact specifications. CNC machines can often handle tolerances as tight as 0.0005” and manage various materials, including versatile ABS and Vespel.

Operations include plastic CNC turning. This process can create exact details like contour, form, taper, straight turning, and internal and external threading. Alternatively, CNC milling facilitates drilling, boring, pocketing, and thread milling. This can fashion parts from plastics such as acrylic, glass-filled nylon, and PVC for applications in various industries.

Injection molding is a process that allows for the manufacture of high-quality parts. Molten materials are injected into molds, explicitly fashioned for each piece. However, the entry cost of this process is often high and the turnaround slower, as more preparation is required.

This is an additive process in which plastic is layered to create a precise 3D shape. The printing process is easy and allows for a high degree of design freedom. However, 3D printing often produces poor surface quality and requires post-processing for a high cosmetic standard.

3D Printing can be great for prototyping small parts from an ABS-like material. While not intended for actual use, these parts can help you economically assess design considerations.

Suppose your part is a new development that will feature essential applications. In that case, it’s crucial to get the design just right. In this case, you might contact a vendor to only create a small number of parts to test. Prototypes can reveal problems in the design or material that can be improved upon before you start higher volume production.

Not all plastic manufacturers are flexible where small quantities are concerned. However, Severna offers prototypes and small production runs thanks to their precise CNC machining. This allows us to create a fully functional prototype with the desired materials and accurate tolerances.

We hope that having read this blog post you now have a better idea of how to get plastic parts made.

With Severna, you can get a turnaround on your quote in just 24 hours. This means that you’ll quickly be able to decide whether you want to produce your parts with us. Severna has been a leading manufacturer of precision plastic components refining its process since the 1950s. We are AS9100 and ISO 9001 certified and provide our customers with the best quality and service in plastic manufacturing.

Choose us if you’re looking for a tight turnaround time for prototypes. Without minimum or maximum run restrictions, we can take on any project, no matter where you are in the development process.

Get in touch today for a quick quote.