Are you looking for exceptionally durable manufactured materials? If yes, Delrin vs. nylon should be ideal options. These versatile materials provide remarkable strength, durability, and lifelong wear resilience. As a result, they are suitable choices for a wide range of injection molding and machining applications.

However, these two materials have distinct features that suit specific applications or project requirements. In this Delrin vs. nylon guide, we will see how these materials compare in terms of uses, specs, pros & cons to help you choose one that suits your precise needs best.

Delrin is the emblem name for polyoxymethylene (POM), a succession of acetal resins that exist as semi-crystalline thermoplastic polymers. Delrin is best known as acetal, polyformaldehyde in the polymer chemistry world. Delrin also exists as a synthetic polymer material.

Different chemical firms use varying chemicals to produce this material. You’ll find it termed differently, including Delrin, Celcon, Kocetal, Ultraform, etc.

Delrin is a great alternative to metal because of its:

It’s a multi-purpose engineering thermoplastic material. That means it’s often used in precision parts that require low surface friction, high stiffness, and great dimensional stability. In addition, Delrin can retain its shape and size even when exposed to humidity and temperature changes.

This smart plastic boasts more excellent mechanical properties than other popular plastics such as polyethylene and polyvinyl chloride (PVC). That’s why you’ll find it tougher and ideal for extreme industrial applications and environments. Delrin shines in wet environments as it has a very low moisture absorption rate, excellent performance, and high dimension retention ability. Therefore, it’s a perfect option for valve and pump components.

This material is also chemical resistant to solvents, hydrocarbons, and neutral chemicals. Its natural grade is USDA, FDA, and NSF compliant, meaning you can use this material in any suitable environment with no worries.

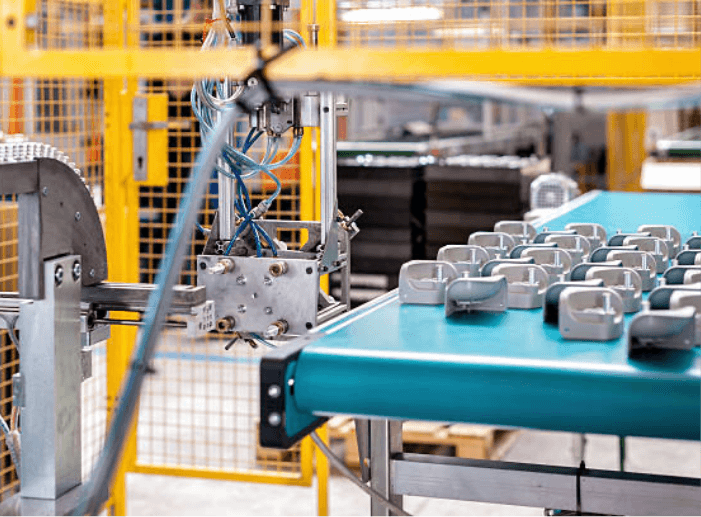

Delrin boasts different uses in various applications, including:

Polyamide or nylon is a synthetic material formed by a group of polymers that often include plastics. Basing on their thermal properties, we can call these polymers thermoplastic manufactured materials.

Nylon material is a result of a synthetic method known as condensation polymerization. It’s a method where monomers like diamines and dicarboxylic acids combine to form peptide bonds. Each peptide bond produces a water molecule as a by-product.

Most nylon polymers are semi-crystalline and contain symmetrical backbones. As such, nylon materials are excellent fibers. However, the name of nylon polymer depends on the number of carbon atoms present in the monomers. For instance, in nylon 6,6, dicarboxylic acid has six carbon atoms, and the diamine has six carbon atoms.

Here are some of the common applications of nylon material:

Nylon and Delrin are essential thermoplastic polymer materials. However, each material has distinct features designed for particular applications. Let’s see how Delrin vs. nylon compare:

Delrin is a thermoplastic material produced from polyoxymethylene, while nylon is a result of reacting amide and dicarboxylic acid monomers. Besides, Delrin is suitable for manufacturing precision parts such as pumps, gears, bearings, rollers, bushings, valve components, etc. In contrast, nylon is ideal for 3D printing, clothing, and strengthening rubber components like rope, car tiers, threads, etc.

If you’re looking for the best-manufactured material for 3D printing projects, consider choosing nylon. The material is also suitable for use in higher temperature scenarios than Delrin. Unlike nylon, Delrin is ideal for applications in wet environments. That’s due to its low moisture absorption rates. Besides, Delrin’s excellent strength and resilience make it best for use in machined and precision parts.

Moreover, nylon material boasts higher abrasion resistance levels than Delrin. You’ll find nylon a more suitable material with more complex geometries than its counterpart.

| Basis | Delrin | Nylon |

| Definition | It’s the trademark name for polyoxymethylene or POM, a polymer material. | It’s a synthetic polyamide material. |

| Material Composition | Polyoxymethylene | Comprises two monomers: dicarboxylic acid and amide. |

| Production | Manufactured through extrusion or injection molding processes. | Manufactured through condensation polymerization by reacting dicarboxylic acid and amide monomers. |

| Uses | Manufacture of bearings, gears, valve components, bushings, fittings, rollers, etc. | Clothing, 3D printing, strengthening rubber materials like ropes, car tiers, threads, etc. |

Delrin and Nylon are incredibly tough and durable plastics that will perfectly fit your dream project or application regardless of the material you choose. These manufactured materials also have low friction, making them ideal for use in precision parts.

However, the choice between Delrin vs. nylon depends on your project or application requirements. You must go through the differences between these materials based on their specs, uses, pros and cons. Go through our guide above and further your research to determine the best material for your needs.

If you’re looking for the best precision machined and molded plastic parts or components, you’ll never get it wrong with Severna. They are a leading manufacturer of custom-engineered plastic parts and precision plastic components for aerospace, chemical, and automotive industries.

Contact them today here or call them via 973-503-1600 to find out more about their vast range of services and request a quote on precision plastic parts.